Dans la même rubrique

- Polytech

- ATM

- EN

- Our Lab

- Lab Facilities

-

Partager cette page

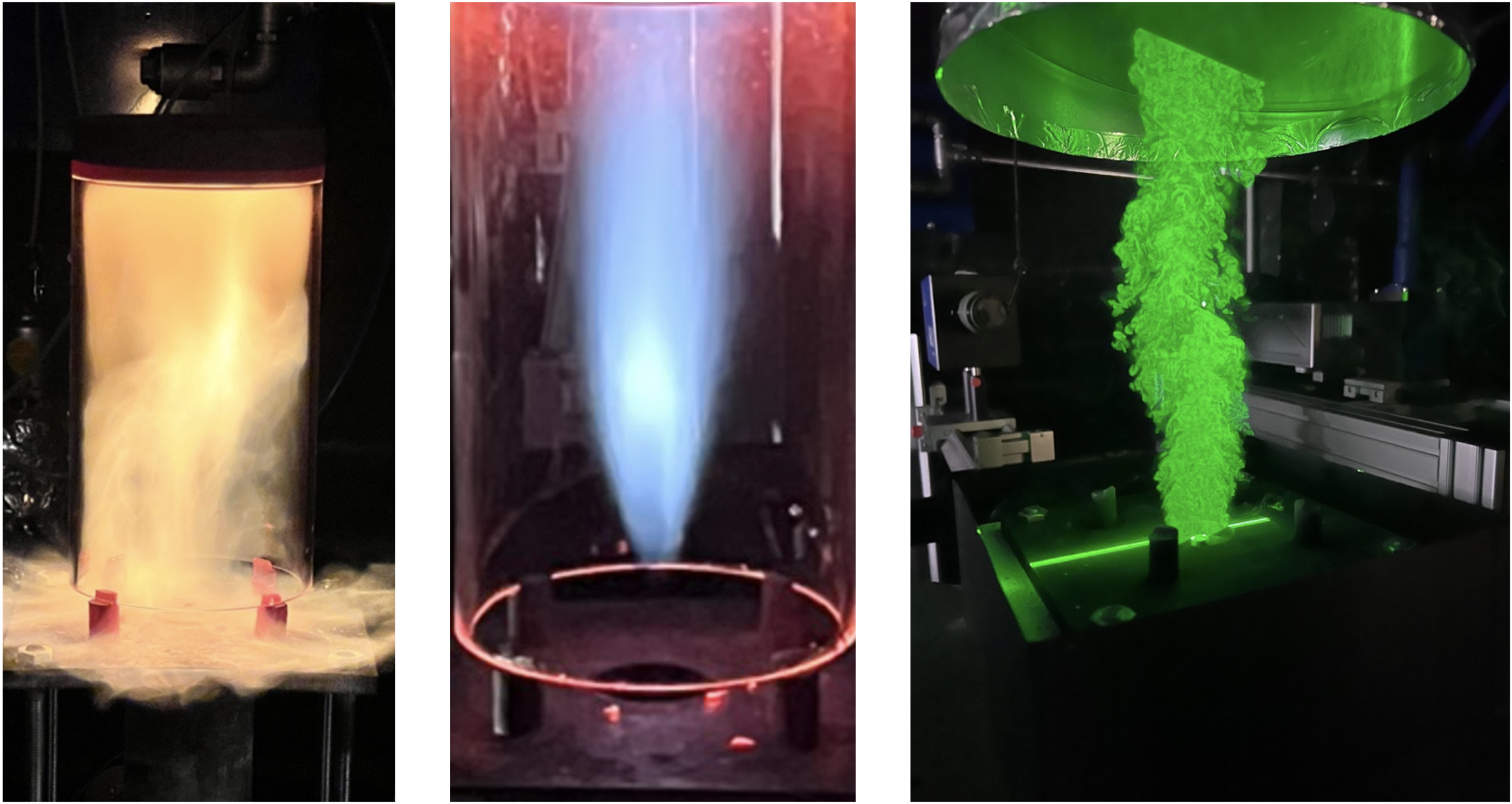

Stagnation-point Reverse Flow Combustor for Micro-Gas Turbine Applications

The facility consists of a quartz combustion chamber equipped with a non-premixed co-flow burner with a flexible power ranging from 5 to 25 kW, and dedicated fuel and air supply units.

The setup is designed for the study of fundamental combustion phenomena under well-controlled laboratory conditions. The rig supports both fundamental and applied studies of low-emission micro-gas turbine combustion technologies.

Unique Capabilities and Highlights

The transparent design of the stagnation-point reverse flow combustor provides optical access for advanced imaging diagnostics, while its modular supply system allows for flexible operation with conventional and alternative fuels.

· High Fuel Flexibility: Can operate with a wide variety of fuels:

- Gaseous fuels: H2, NH3, DME, CH4, CO, natural gas and blends of them, including diluents.

- Liquid fuels: Kerosene-type liquids and alcohols.

· Flexible Operation: Features flexible thermal power (5-25 kW), preheating temperature (up to 650 °C), and air nozzle diameters for adjustable operation.

· Industrial Relevance: Operates under conditions that closely resemble real micro-gas turbines.

Measurements and Diagnostics

Temperatures at various locations within the combustion chamber are measured using thermocouples. Quartz windows provide optical access for chemiluminescence imaging and laser-based diagnostics (PIV, Rayleigh scattering, LIF) with high-speed cameras. The flue gas compositions are measured on a wet basis using two gas analyzers: an Emerson® Rosemount CT5100 continuous analyzer based on the Quantum Cascade Laser (QCL) spectroscopy principle and a Fourier Transform InfraRed (FTIR) analyzer (HORIBA MEXA-ONE-FT).