-

Partager cette page

Our Research

Aero

Aerospace propulsion

ATM owns a test facility to test small Hybrid Rocket Engines up to 10 kN thrust (SLS) with different complete rocket engines or combustion chambers (with or without optical access) using different types of fuels, but mainly with paraffin and N2O as oxidizer. The test engines are completely instrumented, with a separate control chamber from the engine test cell. A strong collaboration is existing with ONERA, Royal Military Academy of Belgium and UnB (Brasil) on this topic.

Aerospace plasmas

Atmospheric re-entry is characterised by a combination of complex physico-chemical phenomena including thermal and chemical non-equilibrium. Predictive simulations using detailed aerothermodynamics models are essential in order to study these phenomena and estimate the generated heat flux during the descent phase. These calculations provide verification of experimental campaigns in ground-testing facilities and are key to design flight experiments. The numerical simulation of non-equilibrium plasma flows surrounding spacecraft during re-entry conditions is a challenging problem because of several aspects: chemical and thermal non-equilibrium, the multi-scale character of the flow and the large number of species and reactions involved. At ATM we use data-driven and machine-learning techniques to reduce the computational time of these simulations.

Aero-engines lubrication systems

ATM has different test benches to test individual components or almost complete loops/systems used in turbofan/turboprop lubrication systems, with single phase (pure oil) or two-phase (oil-air) flows. Specific measurement systems like laser diffraction technique package for oil droplet characterisation or different sensors for debris monitoring in oil or Coriolis mass flow metering are available. ULB-ATM is collaborating with industrial partners using these test benches to develop innovative designs of components and sensors for next generation of aero-engines lubrification systems.

Hydrogen Fuel Cells

Our activities in Hydrogen Fuel Cells are centred on systems studies with applications using fuel cells: a complete and rather unique test facility with a CHP solution using a PEMFC of 4 kWe for household applications, the testing of a H2-fueled FCEV bus with data gathering during normal customer operations in the city, the implementation of a system with a reversible PEMFC-electrolyser for daily and seasonal electricity storage for households or SMEs with local (decentralised) H2 production and storage, H2 PEMFC propulsion for drones, feasibility and permitting studies for H2 applications with FC, …

Thermo

Hydrogen and e-fuels

The production, transport and end-use of green hydrogen and the derived electro-fuels will be key technologies in the future energy system. These green molecules are very dense energy carriers, which makes them suitable for the import and the storage of renewable energy. At ATM, we work on the safety aspects of the hydrogen and e-fuels value chains, as well as on the efficient and flexible end-use of these fuels for the production of heat and power. We developed advanced simulation tools and test equipment to maximize the efficiency of e-fuels-based systems and to minimize their impacts on the environment.

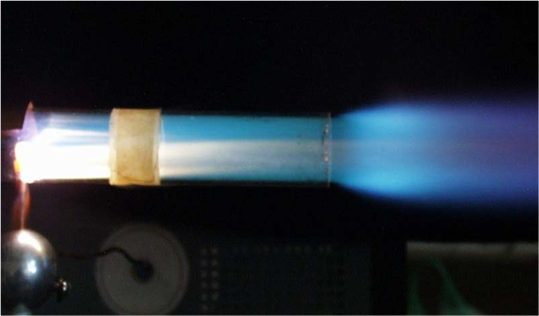

Plasma-assisted combustion

New technological challenges in combustion science require reliable ignition and flame stabilisation under demanding conditions. Examples include ultra-lean combustion, fuel flexibility (using alternative, low-carbon fuels), supersonic combustion (scramjets), and active control of thermo-acoustic instabilities. Non-thermal plasma discharges are proposed as an innovative solution to ensure efficient, stable operation in these regimes. Nanosecond discharges are introduced to enable more favourable ignition of reactive mixtures, where conventional methods fail. Our research aims to fill gaps in the numerical modelling of PAC by conducting a comprehensive study on plasma-assisted ignition and combustion of fuel-air mixtures by nanosecond pulse discharges using reliable surrogates.

Data-driven modelling of thermal-fluid systems

At ATM, we combine strong backgrounds in fluid mechanics and system identification. Building on that foundation, we have developed nonlinear data-driven modelling tools suited to challenging thermal and fluid-dynamics problems involving nonlinearity, unsteadiness, non-stationarity, and turbulence. These techniques can be widely applied, even beyond thermal and fluid mechanics. In combustion, they have been used to tackle major challenges in reacting flows, namely the curse of dimensionality and complex nonlinear turbulence-chemistry interactions (e.g., sub-grid closures).

Advanced combustion technologies

We focus on advanced combustion technologies with strong potential to meet the fuel flexibility expected in the future energy scenario, without compromising energy efficiency and ensuring control of pollutant emissions. In particular, we study MILD/flameless combustion, using both air and oxygen as oxidisers, through a coupled experimental-numerical approach tied by validation and uncertainty quantification. In recent years, we have developed combustion models well adapted to the complex turbulence-chemistry interactions in MILD combustion and demonstrated the feasibility of several non-conventional fuels in this regime.

Heat networks

Heat networks are a convenient way to distribute renewable heat from centralized production units to local heat clients. When environmentally and economically relevant, they can contribute to a significant decarbonization of the heat consumption, that plays a major role in the emission of GreenHouse Gases. When combined to power production, they can also be used as a mean to offer flexibility to the electrical networks. At BRITE, we work on the assessment of the potential contribution of heat networks, as well as on the development of optimal design and operation methods.

Mechanics

Atmospheric boundary layer flows and pollutant dispersion

ATM collaborates on the development of numerical tools for simulating large-scale ABL flows for micro-climate studies and air pollution predictions. In this context, we have developed consistent inflow conditions, turbulence models and wall functions to describe neutral and non-neutral boundary layers in the presence of dispersion phenomena.

Additionally, we have joined our efforts to carry out an experimental campaign for monitoring the indoor and outdoor air pollution in and around several cities in Belgium. Our new projects propose a comprehensive indoor and outdoor air quality management plan for Belgium based on detailed simulations, digital twins and soft sensing.

Thermal-fluid measurements

The characterisation of the performance of energy systems in terms of efficiency and environmental impact is crucial for the validation of the static and dynamic models that we develop and for the quantification of the related uncertainties. We work on both pilot-scale and full-scale measurements of the performances of windmills and heat & power production units, at small, medium and large scales. We combine conventional and advanced measurement techniques and we collaborate with industrial partners to ensure that our data-driven models are in line with reality, and ready for robust optimisation.

Renewable energy storage

We have a number of activities related to renewable energy storage using PHES (Pumped Hydro Energy Storage), BES (Battery Energy Storage) based on different techniques and experimental tests with Li-Ion and RFB (Redox Flow Batteries) and Va, Hydrogen (mainly H2 compression systems), CAES (Compressed Air Energy Storage), and Thermal Energy Storage (TES). We conduct system studies on combined storage solutions, for example for energy communities, including techno-economic assessments.

Industrial process modelling and control

ATM leverages its expertise in thermodynamics, mechanics, and fluid dynamics to support industrial innovation. Through strong partnerships with various companies, ATM develops advanced models, predictive tools, and process control solutions tailored to industrial applications. Its research focuses on optimizing energy efficiency, improving process reliability, and fostering sustainable industrial practices. By combining fundamental research with real-world applications, ATM plays a key role in bridging the gap between academia and industry.