Dans la même rubrique

-

Partager cette page

ATM-01

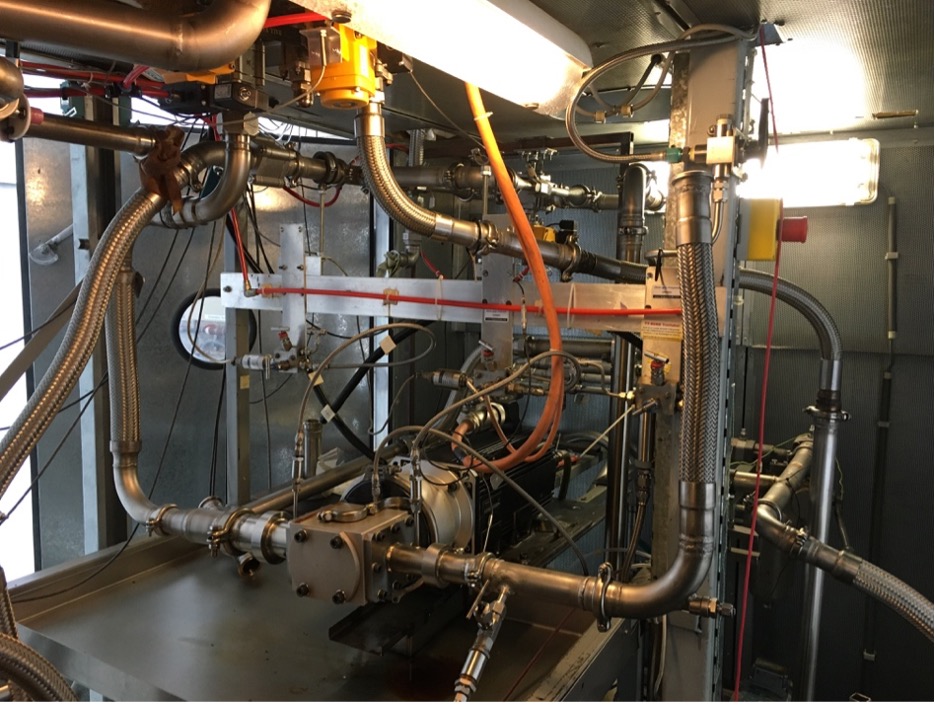

ATM-01 is an aero-engine oil system test rig developed in collaboration with Safran Aero Boosters. This rig is designed to replicate the oil system conditions of a modern commercial airliner turbofan. Its purpose is to test various components of the oil system, including feed pumps, scavenge pumps, oil tanks, separators (de-aerators), filters, valves, heat exchangers (air-cooled oil cooler), sensors, etc.

Tests can focus on equipment design or characterization, endurance testing or contamination assessment (by introducing debris, sand, etc. into the oil).

Multiple volumetric pumps enable high oil flow rates as well as two-phase flows (air-oil), which are typical in the scavenge system. A high-pressure compressor (40 bar) and a 5 m^3 air tank provide high air flow capability. A 90 kW electric heater is used to heat several hundred liters of jet oil to temperature of up to 200 °C. The system is designed to withstand pressure of about 27 bar. A vacuum pump is included to simulate the low ambient pressure experienced at cruising altitude (40,000 ft). The rig is fully equipped with measurement sensors (temperature, pressure, flowrate and density) for both data acquisition and system control. A 20 kW, 11000 rpm water cooled electrical drive is available for testing rotating components such as pumps. Additional specialized measurement instruments are available for specific projects. Optical systems are also available for flow visualization. System control and automation are handled via a PC running LabVIEW, coupled with a PXI-based data acquisition system.